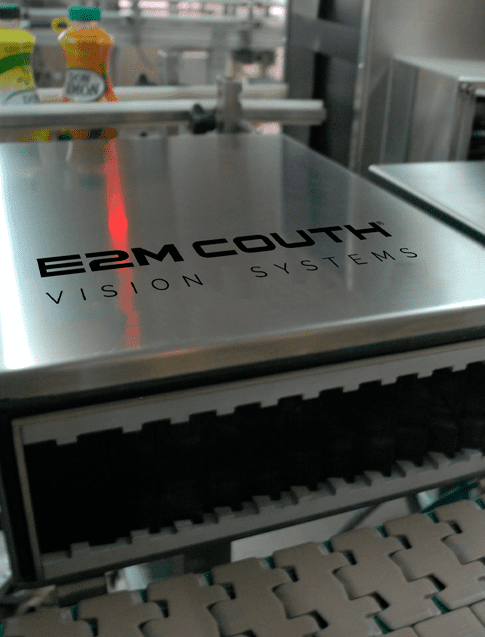

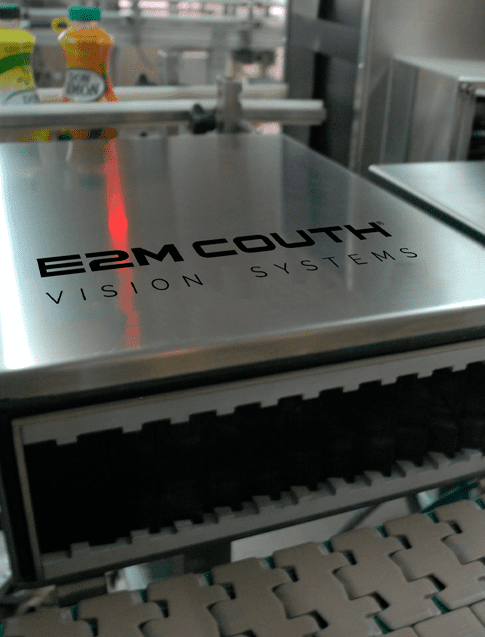

E2M COUTH participates in HISPACK 2024

One more year E2M COUTH will be present at the Hispack fair, the most relevant meeting point for companies and professionals of the packaging sector

We are specialised in reducing costs for poor quality thanks to our artificial vision inspection and traceability solutions.

Inspection systems are intended to examine and measure a product’s features, as well as the components and materials it is made of. They can also be useful for evaluating a particular service or process, using measuring instruments, comparison standards, or testing equipment.

An orientation system is the perfect tool to make all the containers you produce face the right direction. These devices can turn each container 90, 180, or 270 degrees, so that they are placed in identical fashion.

On all production lines, quality is more than an indispensable requirement. Rejection systems are necessary to achieve said quality. There are many reasons why a product may be rejected, which is why E2M COUTH offers the best systems to help improve your production.

E2M COUTH has 30 years of experience manufacturing artificial vision inspection machines for quality control on production lines, with the objective of inspecting, orienting and rejecting 100% of products in real time.

E2M COUTH has a wide range of equipment mainly installed in the food and beverage sector for automatic packaging lines. Thanks to the flexibility of our solutions and the growing need to reduce costs from poor quality in the industry, we are constantly expanding to other sectors, such as chemicals, cosmetics, pharmaceuticals, and automobiles. This all means we achieve profitable growth and all our clients are satisfied.

Get extra quality during production with E2M COUTH!

The implementation of E2M COUTH’s vision systems offer a number of benefits for companies and industries. These systems not only eliminate all quality control problems in the packaging process, but also allow you to see how production quality improves. Below are some of the ways a company can benefit from installing these systems:

They allow product quality to be increased, thanks to their detailed and precise inspection by the machines.

They increase productivity, because these systems can assess where and how problems occur so they can be fixed.

They allow a more precise quality control process. This means no high margin of error, as can be the case due to the visual limitations of operators.

Industries can reduce their low-quality costs. By increasing productivity and reducing losses, companies will be able to make better use of all their resources.

Achieving consistency and meeting all final product quality standards allows all consumer needs and expectations to be met. This is beneficial for future purchases they may make.

As technology advances, there are more and more tools we can implement in different industries and companies, such as the artificial vision systems we have at E2M COUTH. Throughout history, the human eye has been responsible for all tasks, but as these systems appear, it has taken a backstage role, given how precise and thorough these artificial vision systems are.

For those who would like to learn what these systems consist of, we might define them as automated and totally smart methods that make it possible to process and analyse images of products that pass down a packing line in a precise and detailed fashion.

With the algorithms in the image analysis software we developed at E2M COUTH, our devices can detect any kind of issue with the products.

These enables companies to correct any kind of issue, following a series of pre-set parameters. Artificial vision systems are the best tool for product inspection and revision within a production process.

E2M COUTH has a wide range of comprehensive artificial vision system solutions to guarantee an excellent degree of quality on production lines. The technological solutions we offer are present in different sectors, such as the beverage, food, pharmaceutical, cosmetic, automobile, and other industries in general.

E2M COUTH knows that artificial vision systems work at different moments on a production line. All our devices serve a number of purposes to ensure utmost quality once the production process is complete. These are the processes involved and that our artificial vision systems complete:

| Let’s begin with one of the most noteworthy missions on a production line: verifying that the products’ degree of quality meets requirements. For this reason, E2M COUTH has a wide variety of artificial vision systems for in-line inspection, with both standard and special or custom solutions. Ranging from verifying the fill level to labelling and closure, in addition to other inspections. These systems adapt to different needs and industries. |

Our inspection systems have a range of technologies:

| Another major function that takes place within the industrial manufacturing process is product orientation. This process basically consists of turning any containers that are not positioned correctly. E2M COUTH has developed vision systems for orientation. They are able to detect the current position of the bottle and calculate the degrees of rotation required for the mechanical orientation system to turn the container. However, the way the bottle or container is turned depends directly on the type of orientation required, which in turn depends on the type of packaging being used. E2M COUTH has an orientation system with two side bands, which is perfect for the orientation of bottles, jars, bottles, and vials, regardless of whether they are full or empty. It also works with circular and oval cans, plastic, and lids. |

| E2M COUTH can be found in all production processes within an industry. Companies are aware of the major losses that could take place if no quality control process or effective rejection system is in place. All faulty containers on the line are diverted in a stable manner thanks to the rejection systems that complement the E2M COUTH vision systems. The result is a solution to reduce operational costs as well as to meet quality standards and requirements. As you can see in our catalogue of vision systems for rejection, we offer three different solutions. One is our impact rejection systems, which will remove any type of faulty product from your production line with a single blow. We also have the smooth push and bypass systems, which will gently divert faulty products and packaging down another path in the production line. This could be useful for re-working these products in the future. |

E2M COUTH knows that artificial vision systems work at different moments on a production line. All our devices serve a number of purposes to ensure utmost quality once the production process is complete. These are the processes involved and that our artificial vision systems complete:

Let’s begin with one of the most noteworthy missions on a production line: verifying that the products’ degree of quality meets requirements. For this reason, E2M COUTH has a wide variety of artificial vision systems for in-line inspection, with both standard and special or custom solutions.

Ranging from verifying the fill level to labelling and closure, in addition to other inspections. These systems adapt to different needs and industries.

Our inspection systems have a range of technologies:

Another major function that takes place within the industrial manufacturing process is product orientation. This process basically consists of turning any containers that are not positioned correctly.

E2M COUTH has developed vision systems for orientation. They are able to detect the current position of the bottle and calculate the degrees of rotation required for the mechanical orientation system to turn the container.

However, the way the bottle or container is turned depends directly on the type of orientation required, which in turn depends on the type of packaging being used. E2M COUTH has an orientation system with two side bands, which is perfect for the orientation of bottles, jars, bottles, and vials, regardless of whether they are full or empty. It also works with circular and oval cans, plastic, and lids.

E2M COUTH can be found in all production processes within an industry. Companies are aware of the major losses that could take place if no quality control process or effective rejection system is in place.

All faulty containers on the line are diverted in a stable manner thanks to the rejection systems that complement the E2M COUTH vision systems. The result is a solution to reduce operational costs as well as to meet quality standards and requirements.

As you can see in our catalogue of vision systems for rejection, we offer three different solutions. One is our impact rejection systems, which will remove any type of faulty product from your production line with a single blow.

We also have the smooth push and bypass systems, which will gently divert faulty products and packaging down another path in the production line. This could be useful for re-working these products in the future.

Today, artificial vision systems can be applied in different areas, depending on the activities and needs of the production line of any industry. The use of this type of system is therefore closely related to the control and detection of anomalies in the assembly of product parts in areas such as the automobile industry.

Artificial vision systems are also essential for food quality control within the food and beverage sector. This type of system allows a great deal of control, such as the proper closure of containers, key to ensuring quality.

We can also see how vision systems are applied in other areas, such as electronics. In this case, the work of artificial vision systems is focused on assembling parts and welding them correctly. This is a job that requires very high level of accuracy that often cannot be performed by an operator.

The application of artificial vision systems is clearly essential in a wide range of industries. As a result, it has become a key part of the production sector of any industry. E2M COUTH offers you the best vision systems to ensure high productivity quality.

This is the job that artificial vision systems do in different sectors:

E2M COUTH’s artificial vision systems are capable of detecting any kind of defect in food containers, such as stains, breakage, and deformities. As far as beverages are concerned, they can analyse whether their fill level and labelling are correct, or if there is a foreign object or contaminant.

This means the system achieves a uniform, high-quality product. Lastly, as mentioned before, they can verify the label so that all the products are perfectly packed.

With medication inspection, artificial vision systems are in charge of verifying the integrity of the packaging, the presence and proper position of labels and bar codes, and for detecting defects in tablets, capsules, and blister packs, in addition to other drug formats.

In quality control, these systems seek to identify manufacturing errors. They also track and review proper packing and labelling for pharmaceutical products throughout the entire manufacturing process.

The automobile industry is extremely precise and also requires the use of artificial vision systems. These systems are in charge of inspecting the components and detecting defects in parts like batteries to guarantee the quality and safety of the car.

In the chemical product industry, artificial vision systems like the ones we have at E2M COUTH are also necessary. These systems make it possible to control and inspect the containers. Their operation is based on a series of spectral detection mechanisms that can recognise any element that should not be in the container, as well as other aspects, such as the fill level in the containers.

Artificial vision systems work with digital cameras to take images of objects or settings. These images undergo an analysis and processing process, using specific software and algorithms. The process begins by capturing the images, where the digital cameras record the scene or object of interest.

Later on, the captured images are pre-processed to improve the quality and clarity of the image. This might mean adjusting brightness and contrast, noise reduction, and distortion correction. Then, these images are segmented to identify and separate the regions of interest, such as objects or specific characteristics. This segmentation might be based on criteria like colour, texture, shape, or edges.

Once the regions of interest have been identified, relevant characteristics are extracted from them. These characteristics can include shapes, colours, textures, sizes, and more. In the next step, they use image processing techniques and algorithms to analyse and process the extracted characteristics. This could mean using filters, pattern-recognition algorithms, or automatic learning techniques to conduct tasks like object detection, classification, recognition, and monitoring.

With the results obtained from the analysis, a series of specific actions or decisions are taken or made, which may include classification of objects, detection of defects, or monitoring of these objects in movement. After these results, a graphic user interface is provided, or they are sent to other systems or devices for later analysis.

Artificial vision systems are an essential element in modern industry for many different reasons. Firstly, they are a highly valuable tool for quality control. Since these systems have the ability to identify defects and anomalies with precision and consistency, they surpass human capability. This capability significantly improves the quality of the end product and reduces the number of defective products that reach the market, which, in turn, strengthens the brand’s reputation and consumer trust.

Moreover, artificial vision systems significantly contribute to increased efficiency in the industry. Automating processes through these systems means you can conduct inspections and repetitive tasks quickly and precisely. This not only makes production fast, but also reduces moments of inactivity and optimises resources, which translates to a general improvement in operational efficiency.

Another important aspect is cost reduction. By identifying defects and errors early in the manufacturing process, vision systems help to avoid waste and re-working. This reduction in operational costs can be considerable long-term and increase the company’s profitability.

In terms of regulatory compliance, vision systems are vital to guarantee that the products meet quality regulations and standards established by competent authorities. By conducting precise and documented inspections, these systems guarantee compliance with standards and help to maintain the company’s integrity and reputation on the market.

In addition, there are a series of advantages that industries can obtain by using artificial vision systems. They are:

Artificial vision systems like the ones we offer at E2M COUTH can conduct inspections and measurements with a precision and consistency that surpass human capability. This enables industries to guarantee reliable, replicable results.

Artificial vision systems like the ones we offer also automate repetitive and laborious tasks, which increases efficiency and frees up workers to conduct more complex tasks with greater added value. In addition to reorganising your staff, you can make processes faster.

These artificial vision systems work at high speed and can process images and data much faster than humans. This means you can conduct inspections and decisions in real time in settings that require high speeds.

These systems can easily adapt to different settings and lighting conditions, as well as possible changes in production or the articles to be inspected. This is all done by configuring specific parameters and algorithms.

The artificial vision systems we offer can detect defects and anomalies during the first stages of the process, reducing the number of defective products that reach the market and the costs associated with having to do the work over again.

Quality control is a fundamental aspect within any industry,, which is why it is important to know that these systems have improved capacity to inspect and control product quality, identifying defects, variations, and errors, always quickly and precisely.

Since they improve the efficiency and quality of the production process, these artificial vision systems can help to reduce the operational costs associated with waste, redoing the work, and errors that occur in production.

Regulations are a key aspect in many industries. When you use artificial vision systems, you can comply with quality regulations and standards established by competent authorities with precise and documented inspections.

Artificial vision systems have become a key part of today’s largest manufacturing industries. The best way to ensure the utmost quality of your food, beverage, or other production is to implement vision systems that take care of these tasks.

New technologies enable us to verify how the production of companies can increase exponentially, thus ending the risks of faulty products thanks to these systems. This ensures that no factory will have to deal with possible poor quality product complaints, thanks to the work of these technological devices.

At E2M COUTH, we began working in the early 90s. Since then, we have not stopped offering the best vision system solutions to achieve the best results in your industry. If you have a factory and need to improve production, save money, and make faulty products a thing of the past, our vision systems are just for you.

These are key for the inspection, orientation, marking and, above all, the rejection of all damaged or poor-quality products.

If you’re thinking about trying our systems in your industry, contact us and we will help you choose the one that best fits your production line!

Lastest news

One more year E2M COUTH will be present at the Hispack fair, the most relevant meeting point for companies and professionals of the packaging sector

In this digital age, the label inspection system has become a fundamental pillar to guarantee the integrity of end products in multiple industries. By using

In any kind of industry, quality control is a key process. This is because it ensures that each one of the products that leave your

Starting January 1, 2024, wine and distilled spirits products were added to the California Beverage Container Recycling Program (BCRP). As such, wineries and distilleries will

In industry, where technology and automation are taking on ever greater importance, artificial vision is a term that is taking on considerable impetus. This fascinating

In recent years, the industrial sector has undergone a considerable increase in competition, so precision and efficiency for quality control have become a key aspect